Basic 6L80e/6L90e tuning guide.

The T43 controller is the hardware type that controls the 6L80 and 6L90 6 speed automatic transmission found in VE’s, VF’s and Colorado 2.8’s which are found in Australia and New Zealand delivered vehicles. This transmission and transmission controller can be found in other vehicles too and may apply to this basic document.

This guide is just a basic document to assist the everyday tuner or home enthusiast to begin tuning. We will not be discussing the shift point scheduling as this is subjective and very self-explanatory.

Torque Converter Control

When fitting a hi-stall converter to a VE or VF with the 6L80/90e transmission with the T43 TCM controller. You must follow the below procedure to make the calibration accept the mechanical modification you have just performed.

- Open the Transmission tab in your vehicle’s calibration in VCM Suite.

- Navigate to Torque Converter > General.

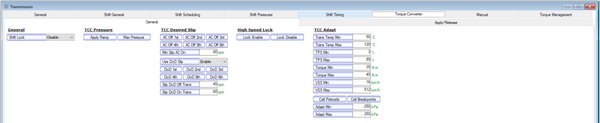

- Locate the TCC Desired Slip section. (Pictured below)

- For the A/C Off section – you must ZERO/0 each individual gear.

- For the Use DOD Slip section – turn the switch to Disabled and then ZERO/0 the individual gears also.

- Next, click on the Apply/Release sub-tab. The next step is very subjective to stall speed, vehicle combination and driver’s opinion.

- A good start is to max out the 3rd and 4th gear converter lockup parameters. Shown below.

- If you choose to raise or lower the 5th and 6th gear converter lockup/apply, please ensure you raise the release by the same number or percentage.

Torque Management (Engine)

Torque management is controlled by either spark control and/or throttle control. There is no maximum torque figure in the transmission to raise for higher horsepower applications within the transmission section. However – we must make sure the Engine Torque Management is setup to allow for more torque to be passed through the transmission.

- Open the Engine tab in your vehicle’s calibration in VCM Suite.

- Navigate to Engine > Torque Management > General

- Locate Maximum Torque – RPM vs. Gear (Max this table out to 8000nm)

- Locate Torque Limit vs. RPM (There will be 7 individual gears – max these out to 8000nm)

- Locate Trans Input Max – (Max this out to 8000nm)

- Locate Trans Input Max – (Max this out to 8000nm)

Torque Management (Transmission)

Now that we have the engine side of the torque management sorted, we can now move onto the transmission torque control. Most of the time you will only see the transmission torque management controlling the engine torque in-between upshifts or downshifts and when moving the selector from Park to Drive or Tap Up, Tap Down (TUTD).

We have found the transmission will last longer with torque management left on. It ultimately does come down to personal preference and application. Transmission reconditioning workshops will usually only warrant their transmissions if the torque management is left on too.

After years of tuning we have found some basic modifications that work well with most modifications, tune only, camshaft and supercharged applications alike.

Navigate to Transmission > Torque Management > Upshift Here you will be presented with a Torque Factor table.

This parameter directly controls how much torque management happens during an upshift. Lowering this number to a .5 or a .7 figure lowers the amount of torque management in the form of spark and/or throttle. Lowering this also lessens the time of the torque management event, greatly improving shift feel and engine responsiveness.

When the torque management event happens, we can also control the amount of spark that is removed by the ECU to lower the engine output torque. The ECU can remove up to 20 degrees from the overall spark figure to control torque output during a shift.

Below is the table that we can modify to lower (or raise if needed) the amount of spark removal that happened during an upshift. This is very subjective to the vehicle in question. Most of the time tuners will zero this table or even raise it to their lowest timing figure in the High-Octane parameter.

Doing this will lower the amount of spark timing that is retarded from the main spark parameter, therefore the engine will not lose too much torque during the shift process which makes the transmission shift feel more positive and precise.

Next, lets look at how quickly the torque is ramped back into the engine post-shift. This is a pretty simple process that makes a world of difference.

Navigate to Transmission > Torque Management > General > locate the Speed Control Terminate switch and set this to IMMEDIATE. By doing so, the ECU will not ramp-in the engine torque post-shift. It will put the required engine torque back to pre-shift as quickly as possible by means of throttle and spark.

The next subject is Shift Completion Time or Shift Timing. Please navigate to Transmission > Shift Timing > Upshift > Locate the two Torque Adder groups. (One is for Normal, the other is for Special)

There will be a table for each individual upshift. The reference RPM and engine torque. We usually remove some shift completion time from these above the 150nm range. Take a percentage from here, for each gear to your liking. Don’t forget to do both normal and special. Normal is when the selector is in normal “D” and special is when you have selected “Sports” or TUTD.

VCM Scanner parameters to log to assist with tuning the transmission.

- ETC Torque Management Type

- Spark Torque Management Type

- Fuel Torque Management Type

- Trans Torque Management Type

- Time of latest Shift

- Trans Fluid Temp

- TCC Slip

- TCC Desired Slip

- PRNDL Status

- Trans Shift Mode

- Time of latest Shift

- Vehicle Speed

- Throttle Position Sensor (TPS)